RESEARCH

Mass Timber Fire Research

Formed to promote and champion timber as a safe material, the Structural Timber Association Special Interest Group offers work packages to provide guidance and evidence to support the fire-safe design of mass timber in High Rise Residential and commercial buildings.

With its well-documented sustainability benefits, Cross Laminated Timber (CLT) has become increasingly popular as a structural framing solution. An engineered timber product in residential applications, made by layering timber orthogonally to give uniform stiffness and stability, it is common to have some or all apartment and room bounding surfaces formed as CLT. The CLT, therefore, creates structural elements and serves a separating function.

In most applications, CLT is lined in some manner with, for example, plasterboard. For commercial projects, the scale of the fire enclosure is much larger, with the CLT generally only forming an exposed ceiling/slab structure. For high-rise residential buildings and similar types of construction projects, the Building Safety Act set out new statutory requirements regarding the materials forming external walls and specified attachments. The STA takes these into account during our research. The STA Special Interest Group and leading CLT manufacturers (including Binderholz, B&K Structures, Eurban, Henkel, KLH, OFR, and Stora Enso) have undertaken the programme of fire performance experiments to provide test-based evidence of behaviour. The findings will enable specifiers and the market to use CLT, fully assured it is a safe building material.

DESCRIPTION OF WORK PACKAGES:

WORK PACKAGE 1 –

DEVELOPMENT OF A COMPLIANCE ROADMAP

WP1 has resulted in the publication of: “Structural Timber Association, 2020. Structural timber buildings fire safety in use guidance. Volume 6 – Mass timber structures; Building Regulation compliance B3(1), V1.1. ed. STA”.

This sets out support to designers in establishing the most appropriate route to demonstrating adequate structural performance in the event of fire, with an emphasis on the English regulatory framework.

It seeks to clarify the structural fire performance objectives that must be satisfied to meet Regulation B3(1), having due regard to a building’s height, use and consequences of failure. By using consequence classes (as defined in Approved Document A) to differentiate performance expectations, the publication gives recommendations as to when the guidance in, for example, Approved Document B (ADB) can apply and when it does not.

It also sets out what evidence the designer should produce when guidance such as ADB is considered not to be applicable as a means of demonstrating compliance with Regulation B3(1), e.g., such as showing that the structure can survive the burn-out of the compartment fuel content and subsequently self-extinguish.

In addition, the STA has published “Experimental study on the impact of adhesive type on the fire performance of hybrid commercial CLT structure”. The report has generated experimental data that can support designers in the evidenced-based realisation of timber-hybrid commercial buildings, focussing on the impact of adhesive type used to bond CLT lamella on premature char fall-off, the likelihood of the auto-extinction of flaming combustion and the associated implications for the structure’s ability to withstand fire.

WORK PACKAGE 2 –

TRAINING AND DISSEMINATION

WP2 has delivered a series of webinars to industry stakeholders outlining the progress made in respect of WP1. A recording is available via: https://hub.leadersmeets.com/sta011020. Further webinars will be held in the future to share the findings of other work packages and to reinforce / promote the use of Vol. 6 of the STA guidance.

WORK PACKAGE 3 –

LARGE-SCALE EXPERIMENTS LITERATURE REVIEW

WP3 has documented the state of the art with regards large-scale fire experimentation and mass timber construction based upon the literature available at the time. The outcome is a freely available literature review report available to download from the SIG information library accessed from this page.

WORK PACKAGE 3a –

SMALL-SCALE EXPERIMENTS

WP3a has been instigated in response to the literature review and in considering how best to generalise the outcomes of large-scale experiments intended under WP5 and WP6, in cognisance of the potential differences in fire performance of CLT between suppliers. WP3a concerns a suite of small-scale radiant panel experiments (sample size 200 x 200 mm x 120 mm thick) undertaken by Efectis to assess impact of:

- Wall and ceiling orientation;

- Supplier;

- Lamella thickness (40 mm vs.20 mm);

- Whether edge-glued vs. not; and

- Adhesive type (heat-resistant vs. regular polyurethane adhesive).

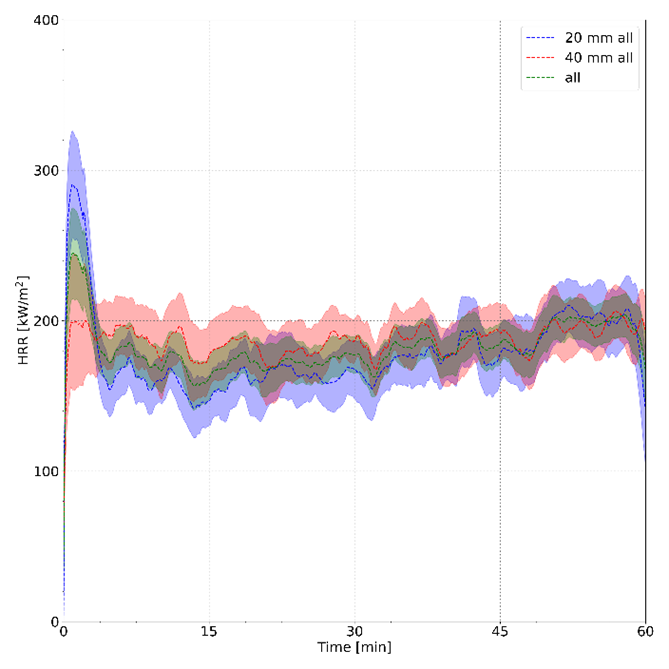

The fire performance across these variables is considered in terms of: heat release rate, sample mass loss rate and in-depth temperature profile. These parameters are measured over a 60 min duration, subject to an incident heat flux of 50 kW/m2.

Fig. WP3a outcome on the comparability of CLT HRR for different first lamella thicknesses.

WORK PACKAGE 4 –

ENCAPSULATION-BASED ROUTE TO COMPLIANCE

WP4 has been developed to set out a model fire strategy for a high-rise residential building (HRRB) formed of mass timber and falling within the scope of the in-effect ban enacted through the changes to Regulation 7 of the English Building Regulations. It sets out key considerations in terms of: encapsulation specification, fire stopping, the interface between a non-combustible external wall and CLT internal members, etc. Finally, the deliverable aims to map available test data for encapsulation solutions, fire stopping details, etc., to identify knowledge gaps where further standard (compliance) testing may be valuable.

WORK PACKAGE 5 –

HRRB LARGE-SCALE EXPERIMENTS

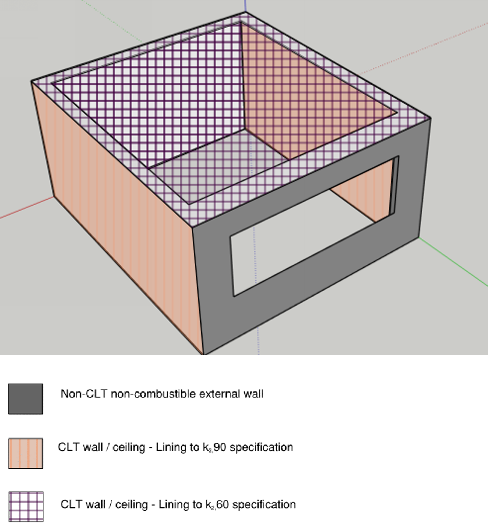

WP5 builds upon WP4 and acknowledges that fully encapsulated mass timber buildings may not be viable from a commercial perspective, i.e., there is an anticipated desire to optimise the extent and volume of protective lining used to internal CLT surfaces. In this regard, up to nine compartment experiments of the scale of 3 m x 4 m x 2.4 m high are planned, utilising a combination of heat resistant and non-resistant adhesive CLT (informed by WP3a). These will be protected to varying extents with plasterboard to establish to what degree linings can be allowed to fail within a protected CLT compartment and how early in the development of a fire this can occur, whilst still observing self-extinction. This will serve to inform the scope to which linings in a HRRB context can be optimised, whilst still ensuring a building has a reasonable likelihood of surviving burn-out.

Fig. Illustrative HRRB experiment compartment with fully encapsulated walls and partially protected ceiling.

WORK PACKAGE 6 –

COMMERCIAL LARGE-SCALE EXPERIMENTS

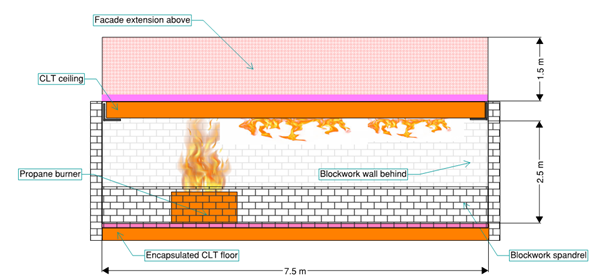

WP6 comprises three large-scale enclosure experiments conducted in collaboration with ITB, Poland. The enclosures are intended to replicate a commercial office-type environment and measure 3.75 m x 7.5 m x 2.5 m high, with one fully open side. A localised fire will be generated via propane burners which will induce flames extending across c. 50% of the ceiling in the 7.5 m direction.

The experiments primarily serve to answer if avoiding delamination is a prerequisite for confidence in self-extinction of flaming combustion, when only a CLT ceiling is exposed.

The three experiments comprise:

1. A reference experiment with a fully encapsulated CLT ceiling to characterise the conditions below a non-combustible ceiling;

2. An exposed CLT ceiling adopting a regular polyurethane non-heat-resistant adhesive (informed by WP3a) to characterise both the change in the conditions below a combustible ceiling (relative to the reference experiment) and the self-extinction behaviour of the ceiling, with increasing extents of delamination depending upon the distance from the burner;

3. An exposed CLT ceiling adopting a heat-resistant adhesive (informed by WP3a). This will serve to provide a comparison of the development of the conditions below a combustible ceiling where delamination is less likely. It will also serve to provide a comparison in the self-extinction characteristics of the CLT slab for a case less susceptible to delamination versus experiment 2, where it is more likely.

Instrumentation will be provided in all three experiments to make estimations of the slab mass loss rate, heat flux from the flames at the CLT surface, heat flux in advance of the fire front and emanating from the ceiling jet, etc.

Whilst the enclosures are relatively modest, the use of a propane burner is intended to mimic the behaviour of a localised or travelling fire in a larger space.

ADDITIONAL READING

For additional reading matter in regard to this project please use the link below